Images from Investigations, Part I: Basic Silver Gelatin Emulsion

Below are images from the first part in our series of investigations into photochemical engineering. Within the seminar, we created five emulsions, each of which followed the same formula but utilized a slightly different mode of emulsification in an attempt to increase efficiency. These emulsions were then used to produce a fifty foot roll of 35mm celluloid, ten feet of 16mm celluloid, and several 4×5 paper negatives and tin types…

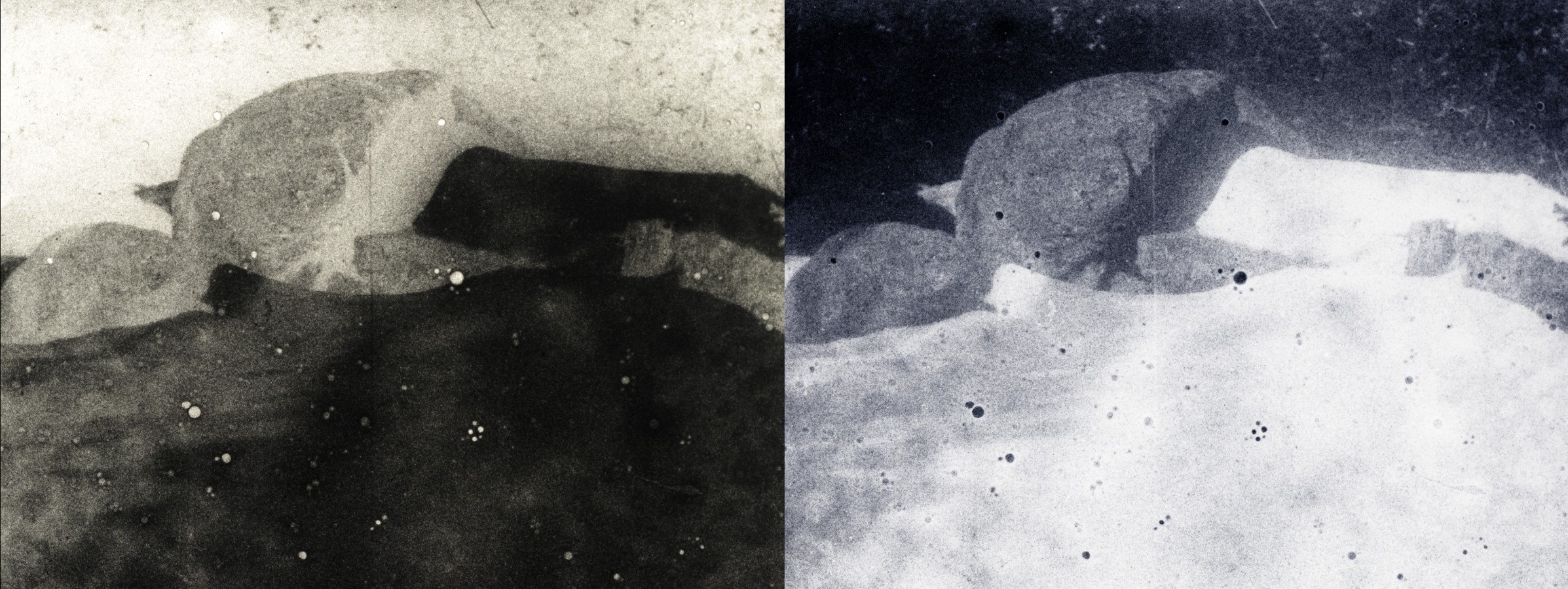

16mm “Test Strips”:

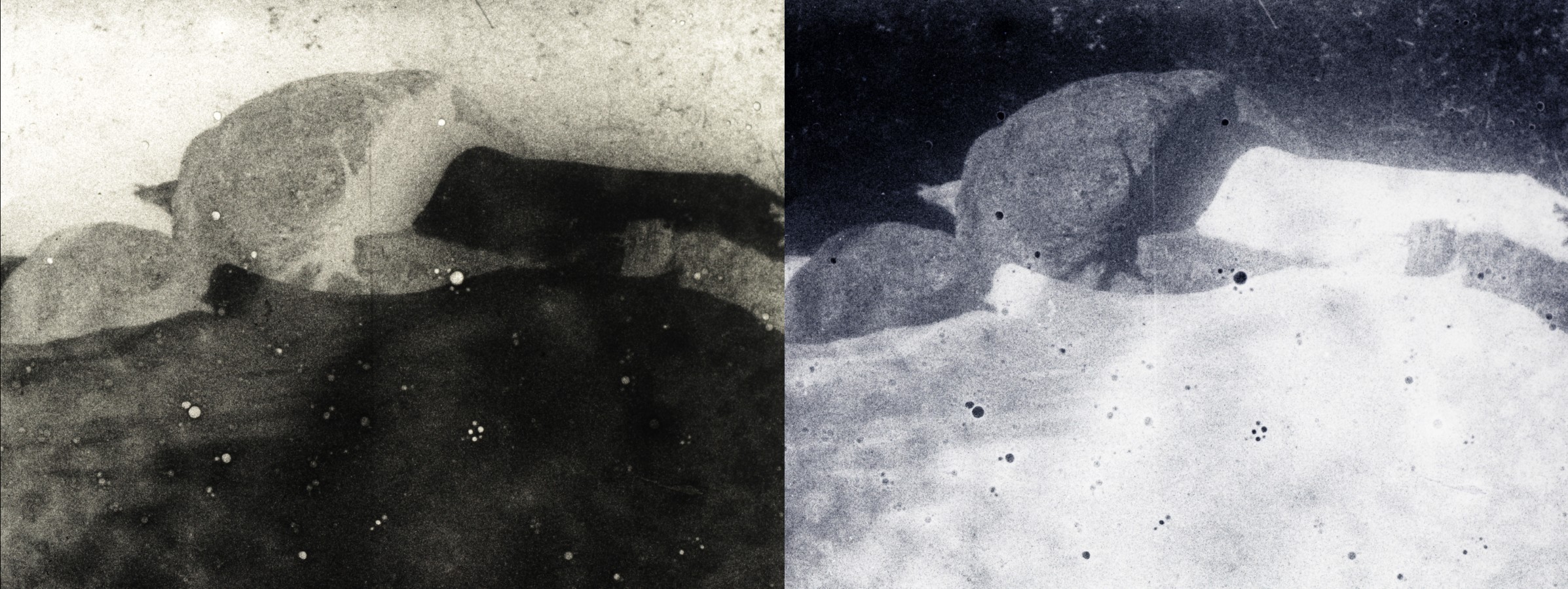

Co-instructor, Robert Schaller (handmadefilm.org) was able to photograph several 16mm “test strips” of each emulsion in-camera, bracketing in between to give a sense of variation in sensitivity between each emulsion. Below are images of the same approx. exposure value (exposure time: 1/65th | f/stop: 2.8) but of two different emulsions: our control, emulsion 1.0, and a variant, emulsion 1.4 which utilized a different emulsification profile to increase sensitivity. The results show that this variation significantly increased density and tonal range…

An additional variable in this test, however, was the fact that the 1.4 test strip was coated a second time using an airbrush. A better impression of this can be given in the following frame by frame transfer of the film strips, rendered at 12 frames per second…

Further sensitometric test will need to be carried out for a greater analysis of the emulsions. In the meantime, high resolution single frames can be downloaded from this directory.

35mm Negative & 16mm Reduction Print:

In the seminar, participants were able to coat a fifty foot length of 35mm celluloid for photography in our hand crankable DeVry. Following it’s exposure, this strip was processed as a negative which was then used to make two 16mm reduction prints on KODAK 7363, High Contrast Positive II print stock: The first print is a 1:2 step print, and the second is a standard 1:1 print…

Scans of the original 35mm negative are forth coming…

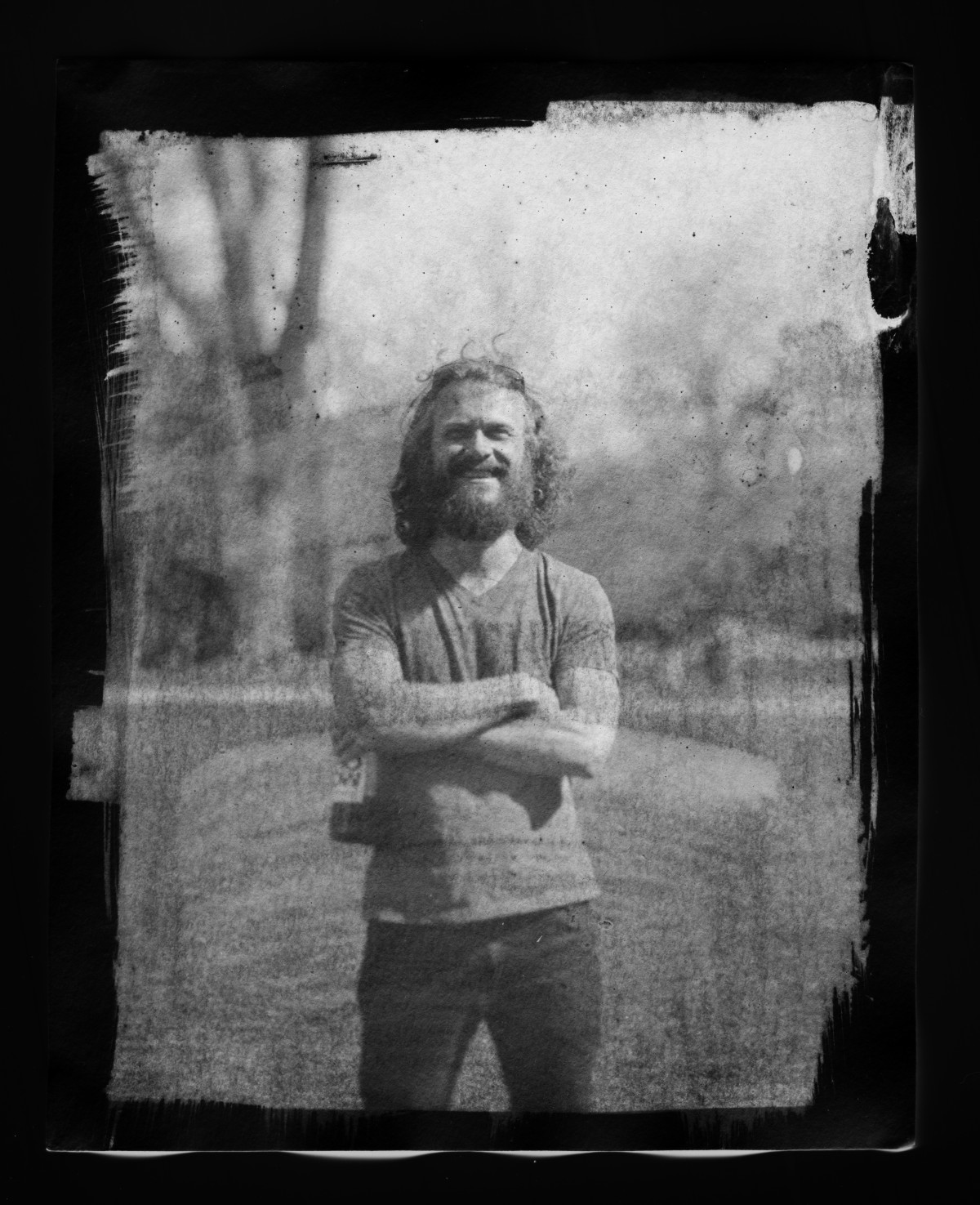

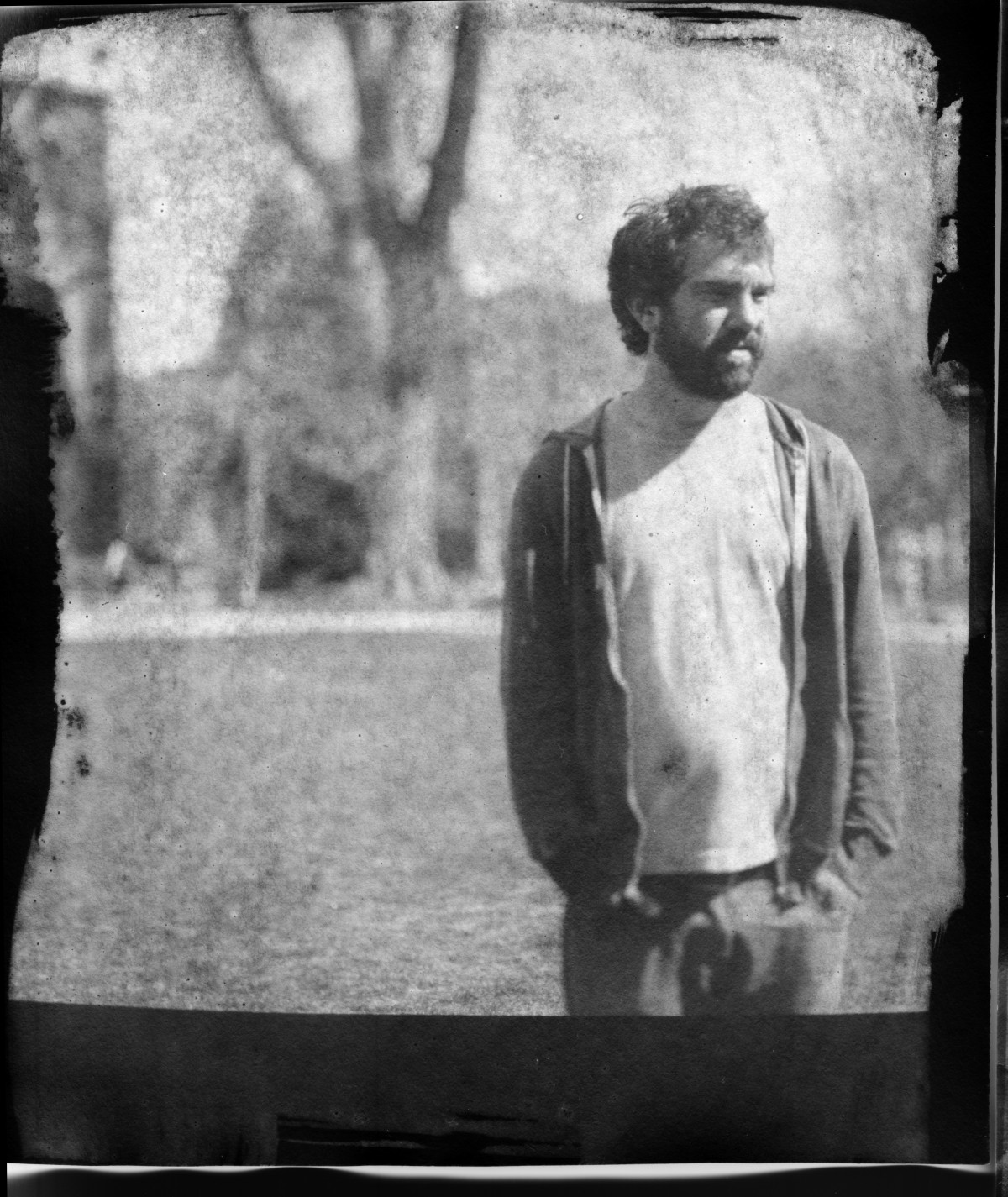

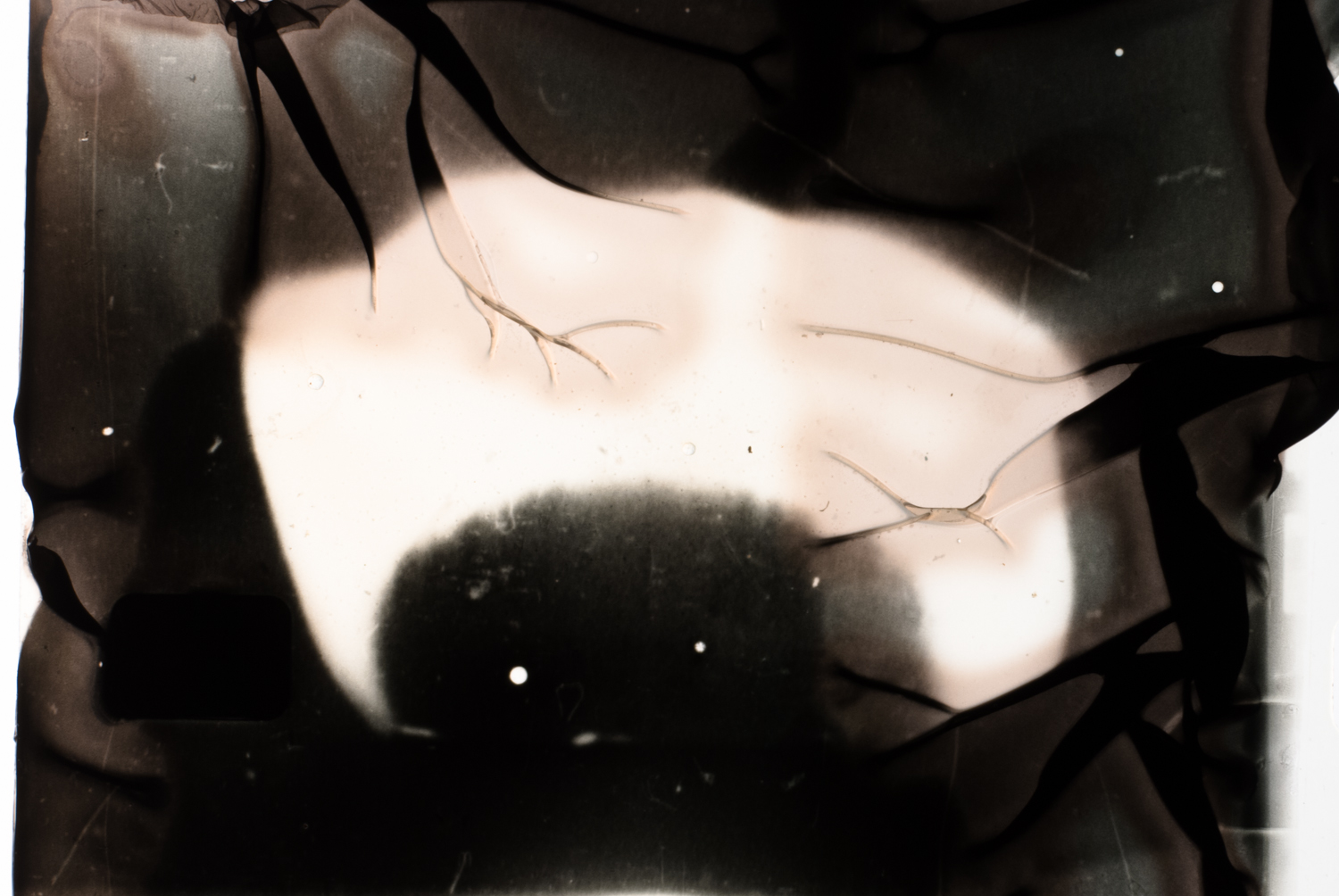

4″ x 5″ Paper Negatives & Tin Types:

Participants were also given access to a 4″ x 5″ large format still camera to use for testing the emulsion. For this, both paper and tin plates were coated with all varieties of emulsion and exposed in camera at an exposure index of 6. Development of the paper negative and tintypes was performed using Kodak D-19 at a temperature of 20 degree Celsius for 2 minutes with a standard agitation profile. In this process, we found that the 1.4 emulsion gave the best results in terms of contrast and density, indicative of an increase in performance. This gain, however, was not terribly appreciative — 0.5 or 1 stop faster — in contrast to Robert Schallers test strips above which illustrate a potential increase of speed of well over 3 or 4 stops. As mentioned before, though, this could have more to do with the coating than with the emulsification, and so further test will need to be made…

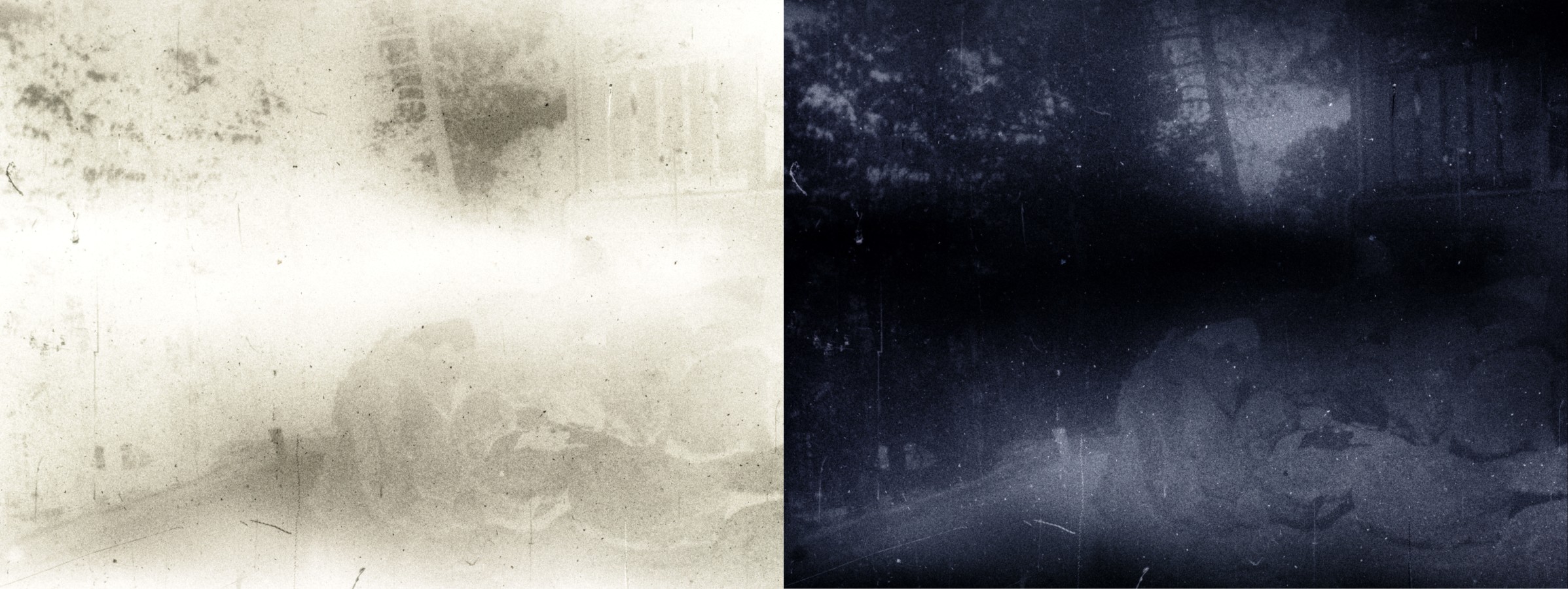

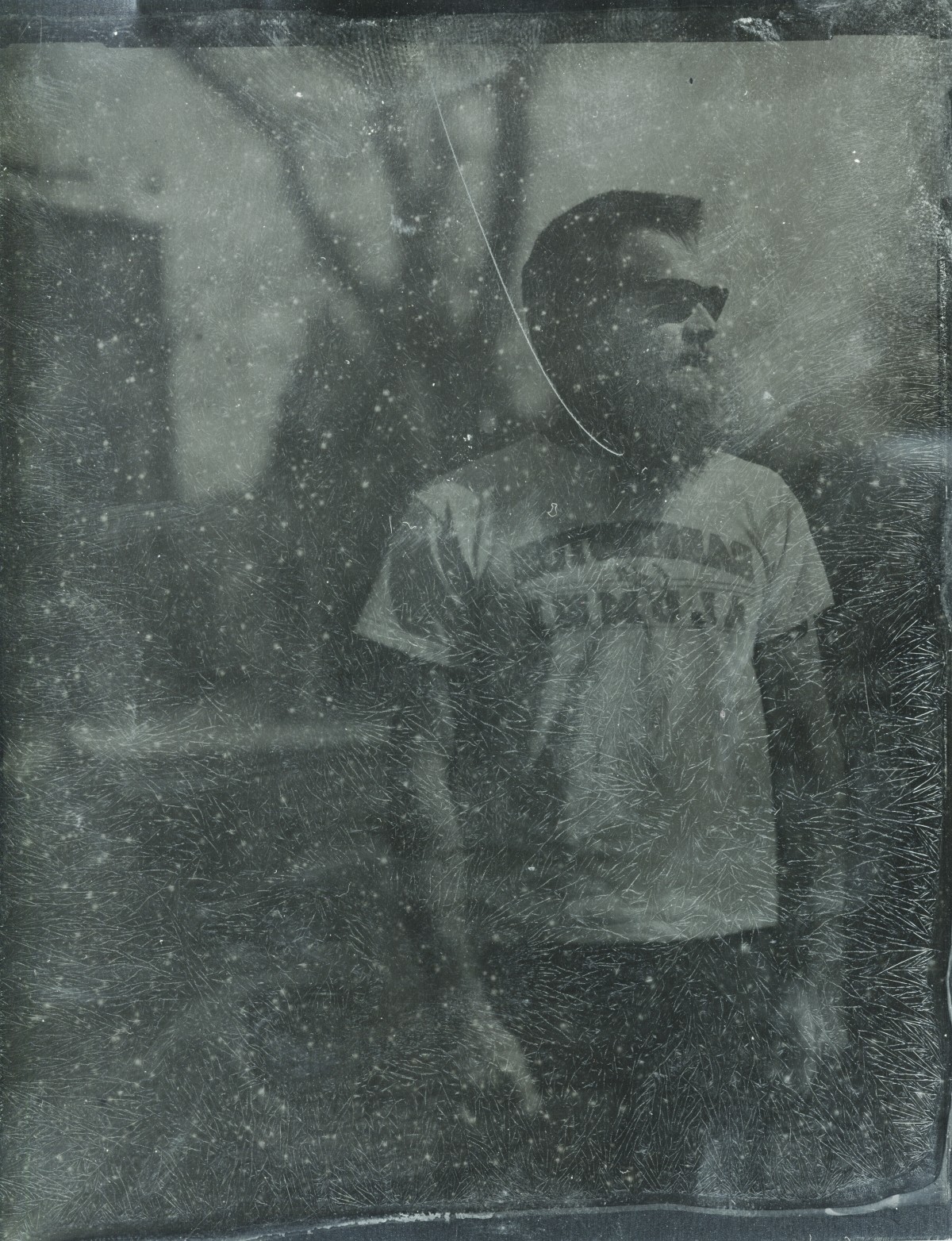

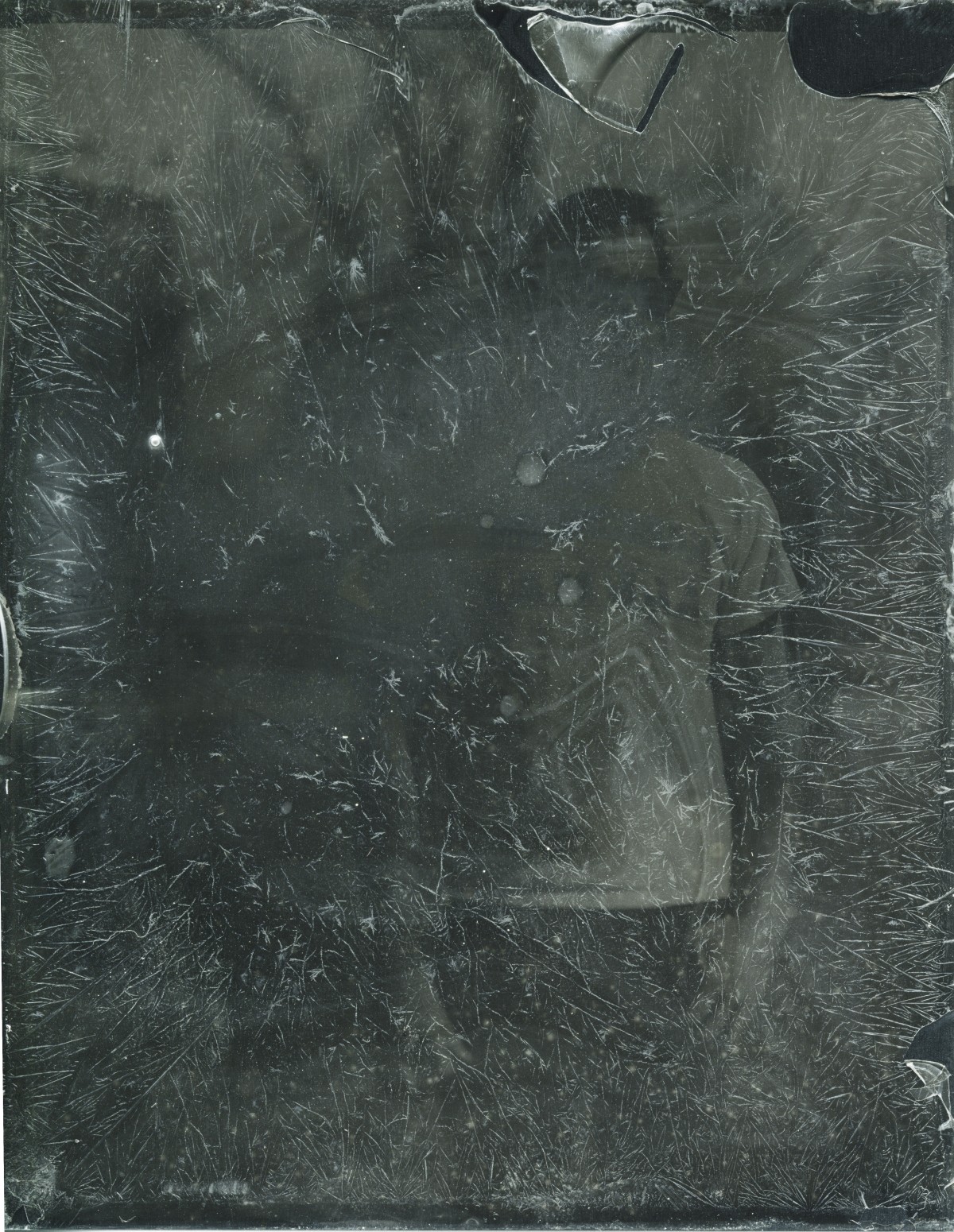

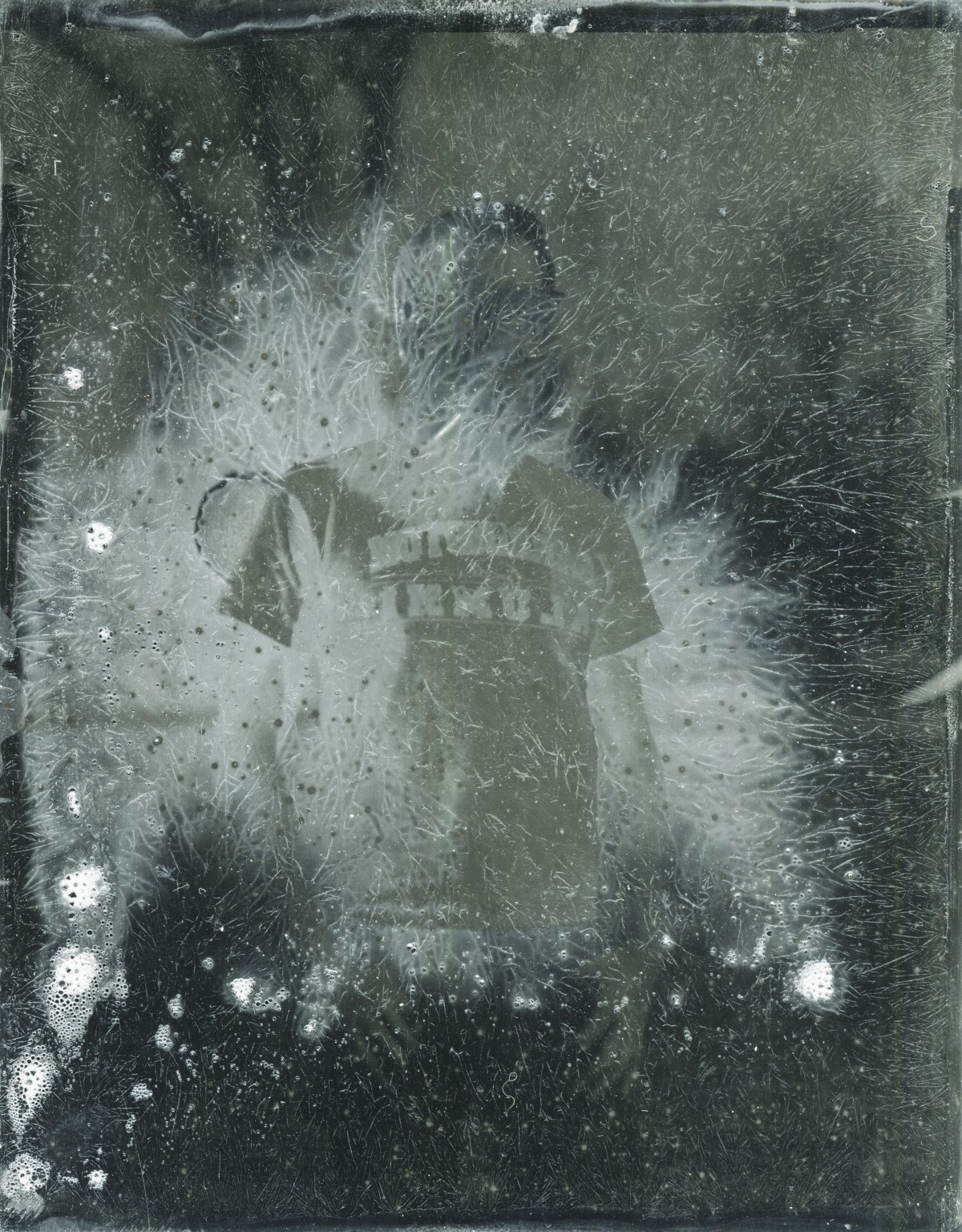

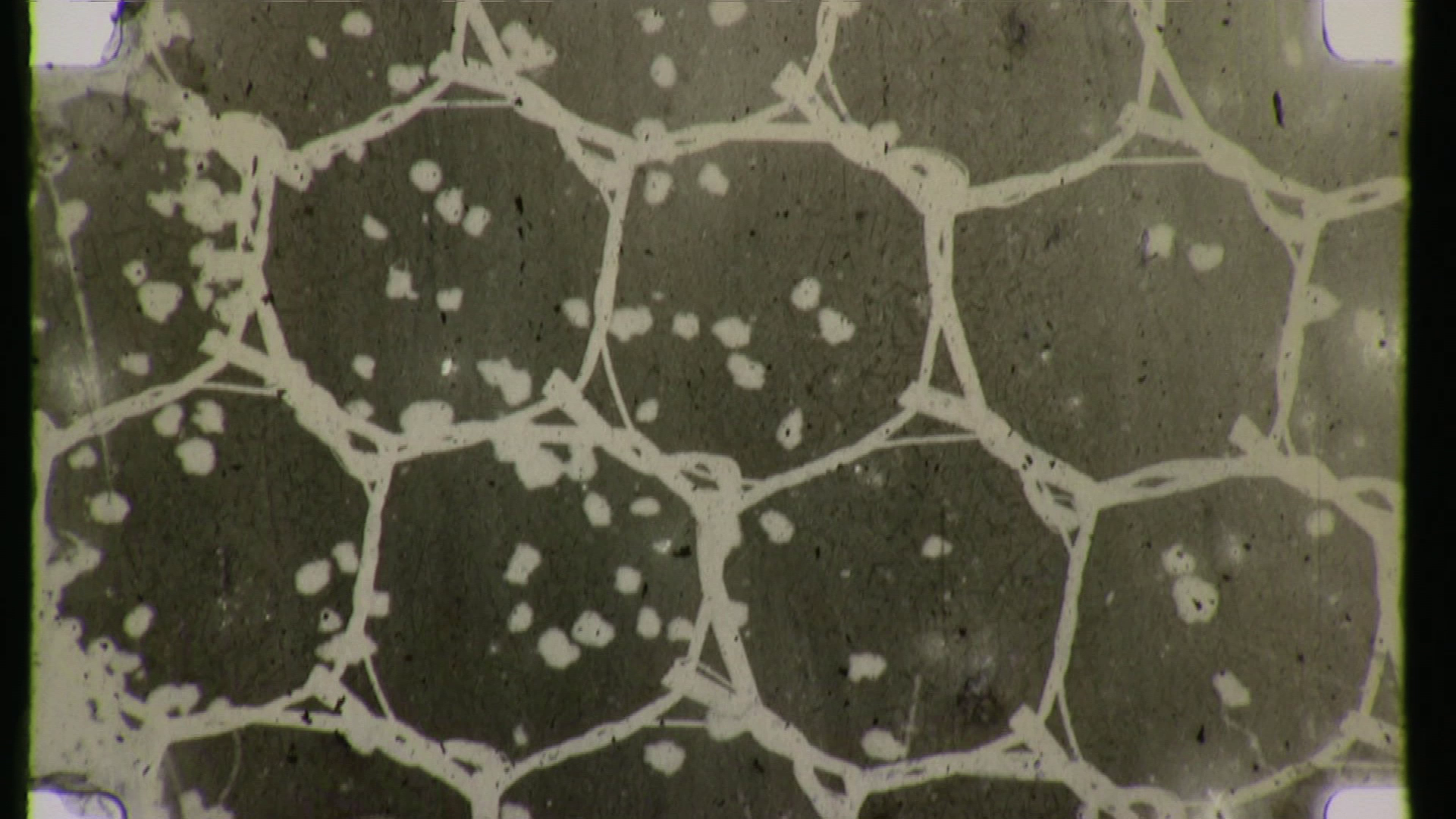

Tin Types:

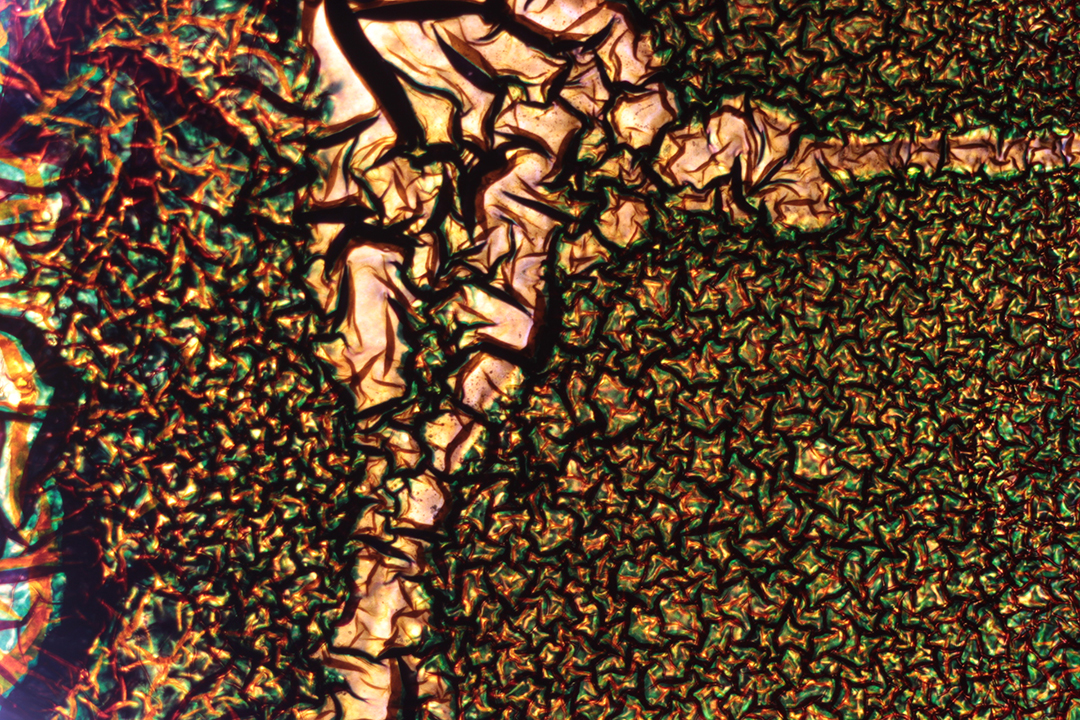

The tintypes below illustrate a significant amount of reticulation (cracking of the emulsion) by comparison to the rest of the materials produced during the workshop. This is likely has to do with the poor subbing of the plates, but could also have to do with the extended fixing times needed for processing the plates. This is because many of the plates had very thickly coated emulsions, sometimes too thick to be adequately processed, such as is in the final image below. Additionally, density and contrast were not quite adequate enough for creating the positive effect desired in tintypes. Our most successful in this regard was the first image below:

Leave a Reply

Want to join the discussion?Feel free to contribute!